- Description

- Features &

Benefits - DOCUMENTATION &

Specification - Stock

List - Custom

Designs - Manuals

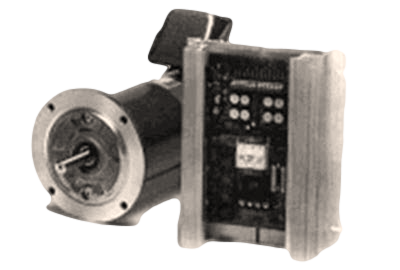

Vari Speed® R400 Series by Hampton Controls

Hampton Controls offers Motor Drives and Motors in Various Speeds

The Vari Speed R400 is a full-wave DC regenerative control that provides high performance four quadrant speed and torque control. The R400 solid state controller converts single phase AC line power into an adjustable DC power to control 1/4 to 2, or 5 horsepower DC motors.

The Vari Speed R400 flexible design is easily select-able for speed or torque mode, tachometer voltage, dual voltage and for horsepower size. The R400 is designed with today's most desirable features including isolated input signals, status indicators, alarm outputs.

When performing frequent directional changes, the R400 transfers excess system energy back to the AC line rather than wasting additional energy by the use of a dynamic brake resistor.

The Vari Speed R400 is designed, engineered and manufactured in the USA, and is UL and cUL listed.

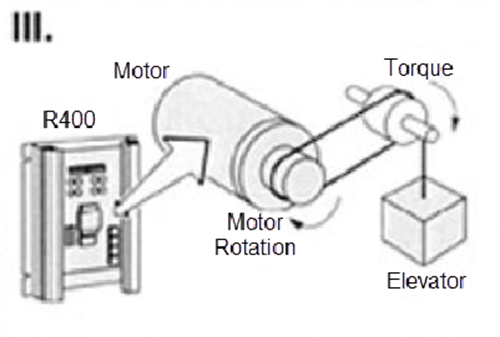

REGENERATIVE (FOUR-QUADRANT) CONTROL

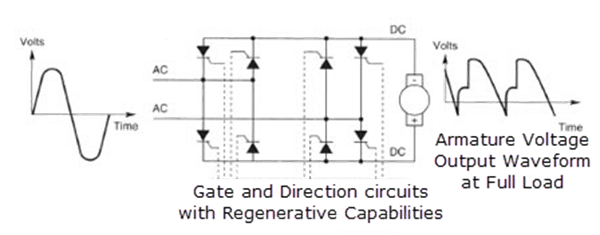

Regenerative DC drives are able to provide complete control of a DC motor's speed and torque simultaneously. A regenerative drive has the capability of producing torque in either braking or motoring modes, while operating a motor's speed in a consistent direction of rotation.

The capability to provide braking torque is a result of the drive's ability to operate in all for quadrants of the motor's speed/torque curve. A four-quad DC drive's ability to operate in a regenerative mode is primarily provided by the additional power section included in the design.

Four additional SCR devices are utilized in comparison to a standard NEMA Code K-type converter. These four additional components allow for the complete control of both the voltage and current flow to the armature of the DC motor, thus controlling both the speed and torque.

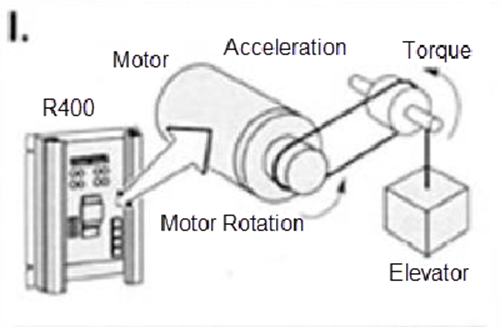

Quadrant I

Forward Motor Rotation;

Forward Torque:

When the elevator is accelerating in an upward direction the torque and speed are in the same direction.

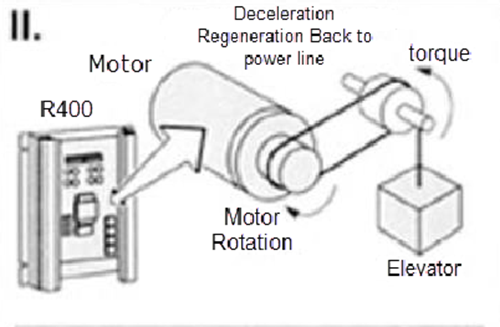

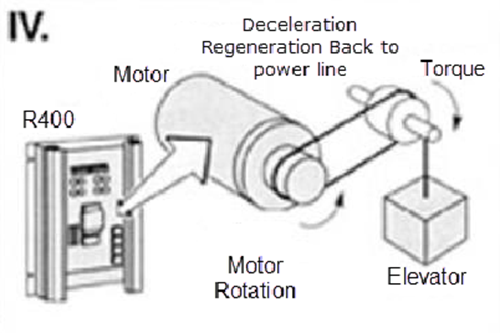

Quadrant II

Reverse Motor Rotation;

Forward Torque:

When the elevator is decelerating in a downward direction, the speed of the elevator is also going downward, but the torque is in the opposite direction and is braking the speed of the elevator. Motor and gravity are being regeneated back to the power line.

Quadrant III

When the elevator is accelerating (faster than the gravity) in the downward direction, the torque and speed are in the same direction.

Reverse Motor Rotation;

Reverse Torque:

When the elevator is accelerating (faster than the gravity) in the downward direction, the torque and speed are in the same direction.

Quadrant IV

Reverse Motor Rotation;

Reverse Torque:

When the elevator is decelerating in an upward direction, the speed of the elevator is still going upward the torque is in the opposite direction and is braking the speed of the elevator. The motion energy rom the elevator and motor are being regenerated back to the power line.

Features

- Excellent regulation performance

- Fast acting current limit

- Starts into a rotating motor

- 50 or 60 Hz selectable

- Provides 150% load for one minute

- Two and three-wire start-stop

- Disable function

- Reversible

APPLICATIONS

- Food and beverages

- Packaging and chemicals

- Machinery and material handling

FEATURES AND BENEFITS

Standard Product Feature | Application Benefit | |

|---|---|---|

Multiple rated unit | One unit can be used for 120 or 240 VAC operation of 1/4 to 2 HP PM or wound field DC motors | |

Regenerative control | Allows 4-quadrant operation to maintain complete control of motor and load | |

Speed or torque control | Provides proper motor control for application requirements | |

Excellent regulation performance | Improves overall system operation | |

Fast acting current limit | Can quickly react and compensate to load changes | |

2- or 3-wire start/stop | Provides flexibility in system logic | |

Isolated logic inputs | Easy connection of peripheral equipment | |

Alarm output | Provides remote indication of an undesirable situation | |

Status indicators | Visual indication of primary control status | |

150% load capabilities | Extra power for intermittent overloads | |

Reversible | Simple external contact closure or + or - 10VDC for motor shaft rotation reversing |

Vari Speed® R400 Specifications

Control Parameters | Specifications | Factory Settings | |

|---|---|---|---|

Input | |||

Power | ----- | ----- | |

Line Voltage (1Ø) VAC ±10% | 120 or 240 | 240 | |

Line Frequency (Hz) | 50 or 60 | 60 |

Control Parameters | Specifications | Factory Settings | |

|---|---|---|---|

PLC or Process Input | |||

Follow Voltage (VDC) | ±10 | ----- | |

Speed and Torque Potentiometer (Kohm, 1/4 W) | 2.5 | ----- | |

Remote Two or Three Wire Start-Stop | On/Off | ----- | |

Tachometer @ 1,000 RPM (VDC) | 7 or 20.8 | ----- | |

Control Parameters | Specifications | Factory Settings | |

|---|---|---|---|

Output | |||

Armature Current Max (Amps, DC) | 10.8 (2.0) | 10 | |

Motor Rating at 120 VAC (HP) | 1/4 - 1 (1/30 - 1/8) | ----- | |

Motor Rating at 240 VAC (HP) | 1/4 - 2 (1/30 - 1/8) | 2 | |

Armature Voltage at 120 VAC (VDC) | 0 ±100 | ----- | |

Armature Voltage at 240 VAC (VDC) | 0 ±200 | 180 | |

Field Voltage at 120 VAC (VDC)** | 100 | ----- | |

Field Voltage at 240 VAC (VDC)** | 200 | ----- | |

Field Current at 120 VAC (Amps)** | 1 (nominal) | ----- | |

Field Current at 240 VAC (Amps)** | 1 (nominal) | ----- | |

Service Factor | 1.0 | ----- | |

Overload for One Minute (%) | 150 | 100 | |

Start/Stops per Minute (Max) @ Full Load1 | 30 | — | |

@ Speed Change 100% | ±12 | ----- |

Control Parameters | Specifications | Factory Settings | |

|---|---|---|---|

Adjustments | |||

Forward Acceleration Rate (sec) | 0.15 - 8 | 4 | |

Reverse Acceleration Rate (sec) | 0.15 - 8 | 4 | |

Minimum Speed/Torque (%) | 0 - 50 | 0 | |

Maximum Speed/Torque (%) | 50 - 110 | 100 | |

Forward Current Limit (%) | 0 - 150 | 100 | |

Reverse Current Limit (%) | 0 - 150 | 100 | |

IR Compensation (%) | 0 - 25 | 12 | |

Dynamic of Loop Regulation | ----- | 50% |

1 Reflected inertial 10.7 lb.in 2 at 1 HP motor (55°C ambient temperature).

*( ) For 176B8013

**176B4001 only

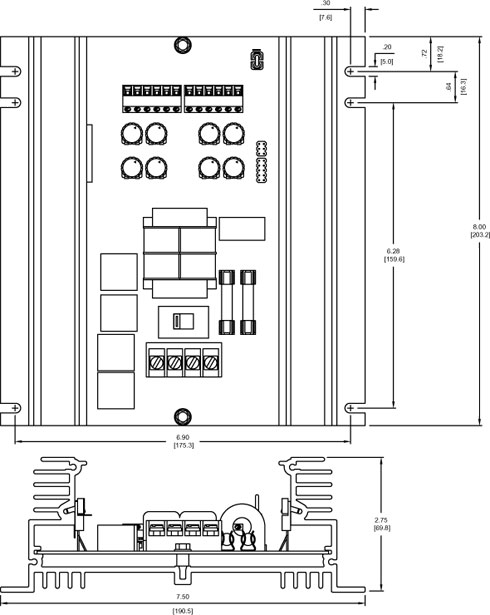

Vari Speed® R400 Dimensions

Regenerative Control Power Section

Selection

Part No. | Description - Chasis Version |

|---|---|

Vari-Speed® R400 - 176B4000 | 120 or 240 VAC selectable |

Vari-Speed® R400 - 176B4001 | 120 or 240 VAC selectable, with field supply |

Vari-Speed® R400 - 176B8013 | 120 or 240 VAC selectable, 1/100 - 1/20 hp |

Vari-Speed® R400 - 176B8821 | 240/230 volt , 5HP, with optional field |

Order Your Vari Speed R400 Series

Hampton Controls looks forward to serving you and supplying you with your Industrial Needs.

Hampton Controls offers a variety of custom built motors. Click on "Custom Build DC Motors" to see a full list of custom built motors.

Feel free to call us if you need any assistance at: 724-861-0150

Download the Free Adobe Reader in order to read the product | |

|---|---|

Vari® Speed R400 Series | |

Vari® Speed R400 Series 5 HP (176b8821) | |

The Hampton Products Company a division of Hampton Controls offers downloadable manuals for nearly every Motor and Motor Drive

Click on "Manuals for Motor Drives and Motors" to see all the available manuals we have available for download.

OBSOLETE MODELS - Limited Manuals Available too.

See our Large Supply by clicking on the Stock List Tab above or Configure your Vari Speed R400 Series

by clicking on the Custom Design Tab above.

Contact Hampton Controls for more info: 724-861-0150

Please call for any special needs, in most cases, we are able to create a custom solution.